Ultimate Guide to Equipment Maintenance Logs

The equipment you have in your company and utilise is only as good as the organisational structure. If it isn’t there, the business is wasting time, employees are annoyed, and clients could be left unserved.

The equipment maintenance logs may differ from one company to the following. However; their fundamental purpose is the same. They are quick and efficient ways to track the state and the “health” of an asset. Complete equipment maintenance log contains essential information about the equipment and an overview of the preventative maintenance that it has been through.

The commitment to a maintenance log that keeps necessary personnel informed on the condition of each asset. Good conditions will allow the business to maximise the use of each piece of equipment. There are a lot of tools like CMMS which can handle maintenance logs. The best maintenance software will eliminate the tedious work of paperwork and update the logs when an order is made. This can help guarantee accuracy and allow maintenance personnel to focus on the work at hand.

Equipment Maintenance Log Definition

It is a form of documentation that companies utilise to document the maintenance of assets. It allows them to track the system’s check-up process and keep track of maintenance tasks carried out by technicians, the precise time when the tasks were executed, and the task’s objective.

Organisations depend on maintenance logs to ensure that the equipment they depend on is operating in good condition and that operations at the plant aren’t affected by unexpected downtimes. They typically put a lot of effort and effort into the upkeep of each asset. If they don’t have a reliable monitoring system for maintenance, it’s not challenging to ignore maintenance schedules and maintenance demands to be out of order.

What’s Inside a Maintenance Log

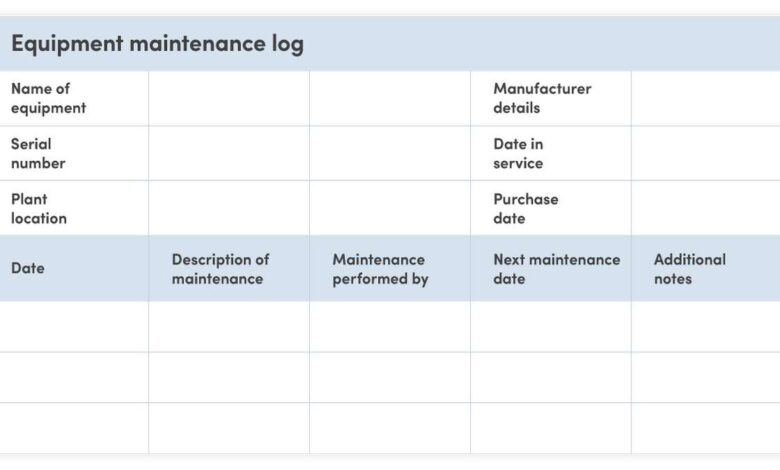

Maintenance logs record the previous actions that were performed on specific equipment. They typically have two sections, each with various kinds of information, which include:

- General Info: The initial section provides general information in identifying assets. It includes information like its name, the machine, the model and manufacturer, the serial number of the equipment, and the location and maintenance technician responsible for the machine. Certain facilities also provide the date of purchase along with the cost.

- List of Maintenance Activities: This section lists every maintenance task that was performed for the property. The information in this section could include the date of executed maintenance, an explanation of the work, along the name of the person responsible for the maintenance task.

A few maintenance logs have an area for comments to record any particular observations that are useful to follow up on in the future or to be followed upon.

Types of Equipment Maintenance Logs

Maintenance Schedule Logs

Maintenance schedule logs provide an inventory of all ongoing projects within an organisation. They provide an overall view of all the projects the company works on at any particular time and an estimated time frame for finalisation.

Machine Maintenance Logs

Machine maintenance logs contain information about scheduled maintenance schedules for every machine used by the company. The logs will ensure that the teams maintain their equipment within the scheduled timeframe to run efficiently.

Project Logs

Project logs record the current projects of the company. Similar to maintenance schedule logs, they assist organisations in assessing ongoing work and anticipated timeframes for completion. Project logs could contain maintenance schedule logs along with projects in other departments. They can also contain completed projects.

Maintenance tasks are essential to maximising the lifespan of an asset. To ensure that maintenance activities are completed consistently, records in logbooks for maintenance have to be compiled and maintained.

When maintenance activities are documented, all employees are informed about the asset’s condition. Being aware of the state of the asset can help improve the plant’s overall performance and make sure that the working environment is safe.

Tips for Managing an Equipment Maintenance Log

Use A Standard Template for Every Asset

Templates for maintenance logs on equipment are plentiful. There are a lot of them, and some are more precise than others. It’s not easy to choose the perfect one, and often businesses end up spending hours, time and money to design their own.

Utilising modern methods for tracking assets eliminates the necessity of finding or creating a template since they can be customised to suit the specific task at the moment.

Keep Your Logs in A Designated Location

It could be easy to lose the binder or notebook in a bustling garage, warehouse or health centre, or even in an office.

It’s crucial to establish a specific place for the log so that every maintenance worker and manager can access it.

Businesses that use asset tracking applications and data storage can keep this information accessible across any device and not worry about losing the documentation.

Create A Routine for Exchanging Logs Between Shift Changes

If the equipment maintenance log it is written in manual form, it’s crucial to establish a procedure to record the items or hand them over during shifts.

Benefits of Equipment Maintenance Logs

Minimise Repair Costs

Inadequate maintenance of equipment is costly for a company. By recording maintenance activities, it is possible to ensure that maintenance tasks are carried out in accordance with the guidelines and that assets remain in good working order. Anything that requires particular attention is mentioned within the Remarks section.

Develop Specialized Maintenance Programs

Every piece of equipment typically comes with its maintenance log. This allows organisations to create customised maintenance programs for every asset. Maintenance logs can also be an excellent source of historical maintenance information that aids in determining the kind of maintenance required for the asset.

Validate Warranty Claims

The documentation of maintenance activities can aid an organisation in proving the case to the warranty claim. It can be proven that the equipment failure wasn’t the result of inattention.

Improve Workplace Safety

Ensuring that equipment is well maintained ensures the safety of the facility and machine employees. The ability to monitor an asset’s health aids in determining when it is time for maintenance before it becomes an accident hazard.

Enhance Accountability

The Equipment maintenance logs also list the person who is responsible for specific tasks. The technicians can be held accountable for the state of assets they manage. This improves accountability among the company’s employees.

Improve the Resale Value

The maintenance logs can show that the equipment was properly maintained and could fetch a higher resale cost.